Although these materials may be nominally pure they usually contain additives which may be present either in small amounts to assist the fabrication process e g as sintering.

Ceramics engineering examples.

Ceramic materials can be identified by their general properties like high hardness brittleness chemical stability and low thermal conductivity.

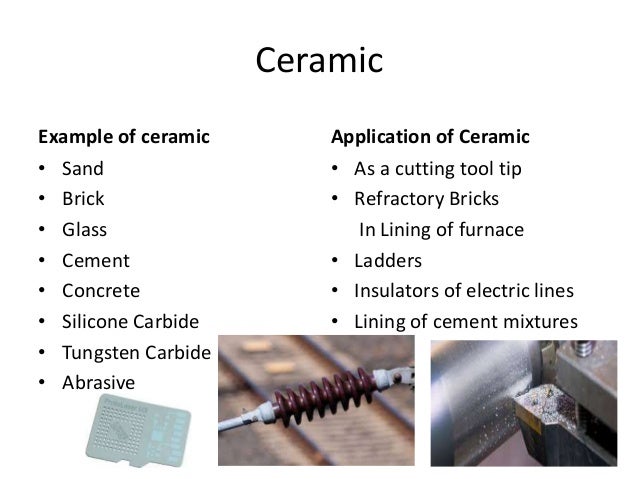

Clay bricks tiles glass and cement are probably the best known examples.

Modern ceramics include some of the strongest known materials.

Alumina aluminium oxide al 2 o 3.

Ceramic engineering like many sciences evolved from a different discipline by today s standards.

Ceramic may be used as a noun in the singular to refer to a ceramic material or the product of ceramic manufacture or as an adjective.

Ceramics is the making of things out of ceramic materials.

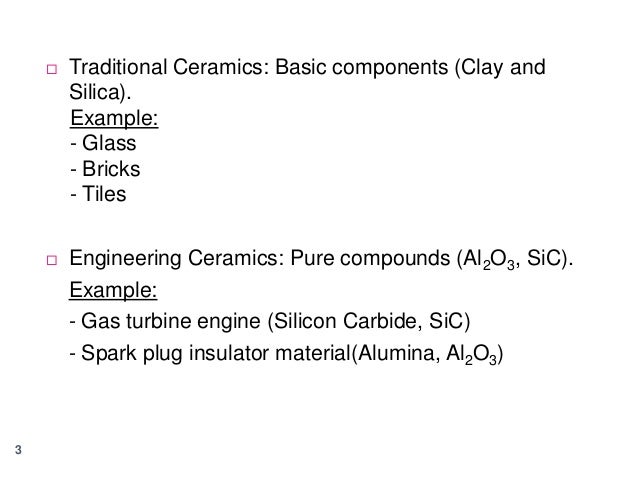

Engineering ceramics are based primarily on pure oxides carbides or nitrides.

These material properties are utilized to produce number of commercial and domestic products such as pottery bricks advanced functional items etc.

The ceramic engineering program prepares graduates for careers as engineers in the ceramic industry and related materials fields.

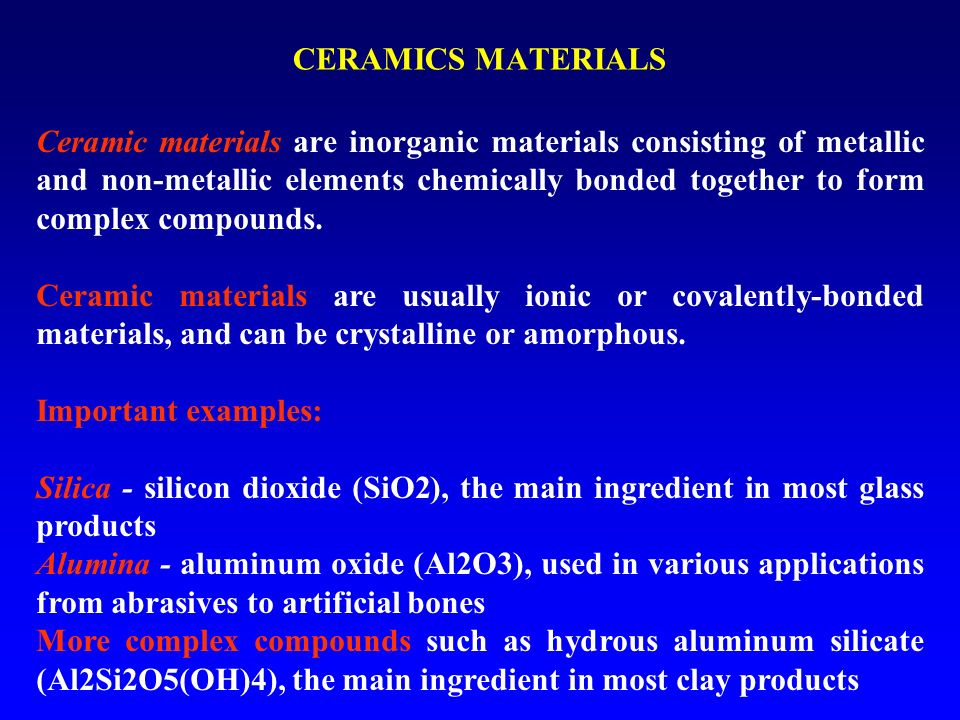

A ceramic is a material that is neither metallic nor organic.

It may be crystalline glassy or both crystalline and glassy.

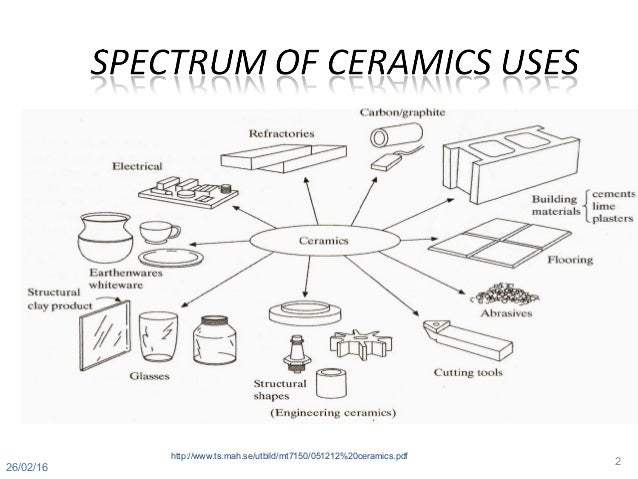

Ceramics are commonly used in construction consumer products vehicles scientific and industrial.

The bauxite is crushed and purified and then heated to 1150 c to decompose it to alumina.

The crystallinity of ceramic materials ranges from highly oriented to semi crystalline vitrified and often completely amorphous e g glasses.

The characteristics of some of the more common are given below.

Common examples are earthenware porcelain and brick.

Ceramics can be organised into types or categories in terms of composition oxide carbide and so on.

As such our graduates are highly sought after by.

A ceramic is any of the various hard brittle heat resistant and corrosion resistant materials made by shaping and then firing a nonmetallic mineral such as clay at a high temperature.

Of these the most important compounds are alumina al2o3 silicon carbide sic silicon nitride si3n4 and zirconia zro2 alumina is made from a hydrated aluminium oxide known as bauxite al oh 3.

Typical examples of bulk engineering ceramics are silicon nitride si 3 n 4 silicon carbide sic alumina al 2 o 3 and zirconia cubic and or tetragonal zro 2.

As part of the new york state college of ceramics the ceramic engineering program is internationally recognized as a leader in ceramics education and research.

Types of engineering ceramics.

For example the silicon nitride used in cutting tools is made by reaction bonding in which silicon powder is squashed into shape and heated with nitrogen gas.

Advanced engineering ceramics are often made in more advanced ways.

Alumina aluminium oxide al 2 o 3 is by far the most commonly used engineering ceramic and is generally specified as the ceramic of.

Ceramics are typically hard and chemically non reactive and can be formed or densified with heat.

Ceramics is a category of hard material that is typically manufactured by heating minerals.

Ceramics are more than pottery and dishes.

:max_bytes(150000):strip_icc()/hands-of-male-potter-holding-finished-vase-in-workshop-665479463-596284a15f9b583f180d5a3c.jpg)