To reduce the heat transfer and hence thermal shock experienced by ceramics at temperatures ranging up to 325 c lee used some nuclear engineering know how that is a two phase heat transfer.

Ceramic thermal degradation.

Phase diagrams thermal expansion and barrier coating degradation august 11 2020 jonathon foreman image above understanding damage caused by environmental silicate contamination to thermal and environmental barrier coatings is important to better protecting turbine blades made from ceramic matrix composites.

Plasma spray ceramic coating is mainly applied as thermal barrier and abrasion resistant coatings 2.

Exposure to temperatures that are sufficient to cause bloating melting or vaporization can change it s form.

Investigated the effect of various oxides.

Bloating is when ceramics turn to rice bubbles like in expanded clay balls used in aquaponics and hydroponics and may o.

Brittle materials especially ceramics are prone to fracture by sudden changes in temperature.

Water can dissolve or deform ceramics that have been low fired i e.

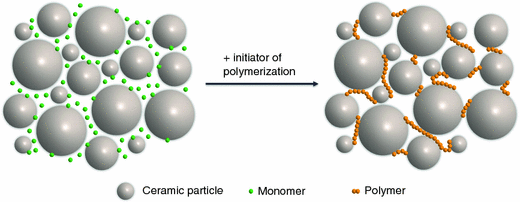

The degradation of polymer composites may be aggravated due to the interaction of a ceramic filler with polymer molecules in the presence of thermal energy from working environments.

A common degradation issue in ceramics involves soluble salts.

In this report we will draw understanding to fatigue in materials with specific emphasis on ceramics what mechanisms and changes to material microstructure can occur to improve resistance to fatigue.

The thermal stability of high performance polymers in an inert atmosphere are generally very good due to their highly crosslinked and aromatic nature.

How does thermal degradation affect ceramics.

There has been a considerable amount of work on the thermal degradation of polymers in ceramic surfaces.

Ceramic matrix composite degradation mechanisms.

Ceramic fired in high temperatures may also be susceptible to water if their mineral particles are soluble in water for example gypsum or calcite.

Therefore to understand the performances of plasma spray ceramic coatings several investigations concerning degradation characteristics including tribological characters and sdhesive strength have been conducted in recent years 3 4.

Asked by wiki user.

Temperatures around 600 c.

Wiki user answered.

A sudden change can cause rapid and unequal expansion.

2014 05 17 16 25 24 2014 05 17 16 25 24.